Evaluate options with reduced toxicity potential

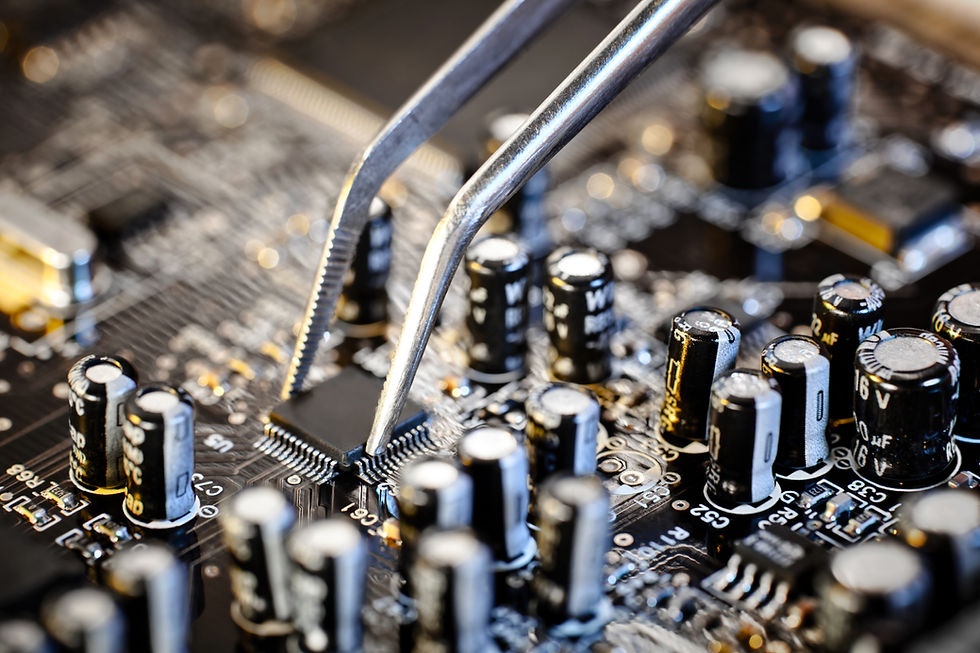

COMPUTER EQUIPMENT AND ACCESSORIES

Alignement sur les objectifs mondiaux

1

Determining Scale

1 -Quick Wins: solution involves adding criteria for the good or service being purchased (ex: certifications), minimal internal process changes.

2 -Long Term Adoption: solution requires some changes to internal processes and/or more capital investment (ex: digital transformation to reduce paper use).

3 – Disruptive Opportunities: requires significant investment and changes to internal processes (ex: retrofitting building)

Le Code UNSPC

Alignement sur les objectifs mondiaux

43

21

0

SDG Target:

12.4

By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

12. Ensure Sustainable Consumption and Production Patterns

Découvrez nos

schémas de collaboration

Lululemon

Lululemon, un leader de l'approvisionnement durable dans l'industrie du vêtement. Engagé en faveur de l'approvisionnement éthique et de la responsabilité environnementale, Lululemon intègre la durabilité dans chaque aspect de sa chaîne d'approvisionnement, y compris l'utilisation d'alternatives biosourcées.

Secteurs d'Avenir

Récompensé par le plus haut niveau de certification (Verte) par My Green Lab en 2023, Future Fields s'est imposé comme un innovateur de premier plan dans l'approvisionnement durable pour l'équipement de laboratoire, en particulier en réduisant la dépendance aux plastiques à usage unique.

The Unscented Company

à la pointe de l'approvisionnement durable en sourçant des ingrédients biodégradables pour ses produits de soins personnels. Leur engagement envers des pratiques respectueuses de l'environnement garantit que leurs produits sont aussi doux pour la planète qu'ils le sont pour leurs clients.

Vous avez une idée pour collaborer sur le prochain modèle ?

Commençons à rédiger !

Étapes du Plan de Projet

Nos modèles par catégorie sont conçus pour décomposer chaque étape du processus d'approvisionnement en six phases, permettant aux utilisateurs de gérer et d'exécuter des projets durables de manière fluide.

Évaluation

• Assess and record what types toxic products is currently in your supply chain.

• Request suppliers for proof of RoHS (Restriction of Hazardous Substances) compliance. Gain insight into the compliance standards of your suppliers.

• Evaluate options to purchase products that are halogen, lead, and silicon free.

• Evaluate the benefit and impact of whole device lifespan and safety from sourcing other options that fit requirements set out by the engineering team and budget - source product with a longer lifespan and better quality.

Identification d'opportunités

Business:

Creating value from trading in circuit boards post recuperation process and reducing the risk of toxic chemicals impact the population.

Sustainability:

Reusing the present toxic chemicals and conflict minerals (if any) to reduce the overall global impact.

Élaboration & exécution de stratégie

• Align with your engineering team to identify the requirements for end-product use (required application of components for the final product to function) and develop a budget for commercial product needs (volume and budget for purchases).

• Ask the supplier if they have ISO certifications, ROHS certifications, and specifications.

• If toxic chemicals are present, then evaluate sourcing from other options that fit the requirements set out by your engineering team without lead, halogens or other toxic substances. Including minimum energy performance standards in technical Request for Proposals (RFPs).

• Create a proposal for procedure change on the decision criteria for purchasing, which includes

(a) searching databases for energy-efficient alternatives when sourcing (such as Energy Star database),

(b) requesting suppliers for visibility into their energy-saving certifications and initiatives to maximize their manufacturing process efficiency.

• Get alignment with your engineering team and other decision-makers to be on board this proposal.

Négociation et contrat avec les fournisseurs

• Ask the supplier for visibility into toxic chemical reporting, ISO-14001, ISO 9001, and ROHS compliance. If commercially feasible, consider negotiating the downstream, product end of life recuperation program with the supplier. Depending on the OEM and reseller, they might derive value in receiving technology end of life.

• Include quality assurance and warranty clauses in the contract to ensure an extended higher quality of the product.

• Consider purchasing in bulk to maximize leverage.

Performance & gestion des fournisseurs

Integrate annual checks for conflict mineral reporting, compliance with warranty/quality assurance clauses, reduced toxicity potential (hazardous waste treated), and WEEE directive regulations (UK). Annual review of value creation tracking metrics.

.png)